Air decontamination in NEST research laboratories - protecting operating personnel and preventing contamination of analyzed samples

Air decontamination in NEST research laboratories - protecting operating personnel and preventing contamination of analyzed samples

Genano rethinks air filtering for hospitals, clinics and laboratories. Genano Technology® is scientifically proven to capture nano sized particles and eliminate 99,999% of microbes from indoor air.

Genano rethinks air filtering for hospitals, clinics and laboratories. Genano Technology® is scientifically proven to capture nano sized particles and eliminate 99,999% of microbes from indoor air.

Superior Air Decontamination that combines:

- Safe patient isolation

- High end microbial elimination

- Patented ultra fine particle filtering

- Chance for improved ISO class

- Removal of VOC gases

- No risks, no usage limitations

- Low energy consumption

- Comfortable noise level

Protection of patients and personnel against airborne pathogens

Particle removal efficiency and total microbial elimination combined with high capacity active carbon

Over 20 years of experience and research in the medical sector

Genano is designed to filter air where HEPA is not enough.

Efficiency and right technology to help your facility reach improved ISO classes

Unique method that relies on capturing and total elimination – no side products released in the air

Genano brings

Boosting the system ventilation and/or creating a pressurized operating room with Genano is a powerful and cost-effective solution especially in

Our units are designed to improve the performance of central ventilation as an additional purification system, to provide constant nanoscale contamination control. Easy maintenance and automatic washing system ensure low lifetime running

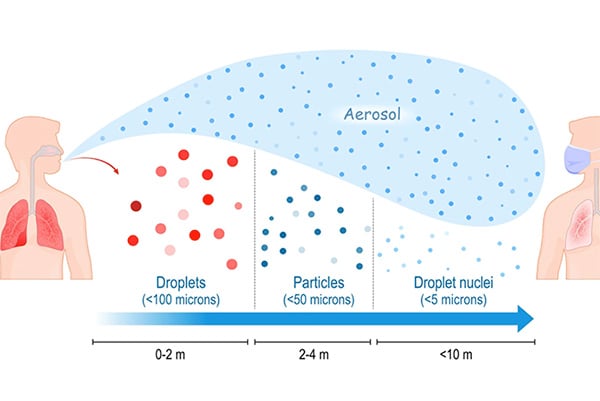

Genano Air Decontamination Units are a rapid and cost-effective way to set up a cleanroom in Healthcare facilities. With our modular, mobile solution a clean room can be set up where ever needed. It is a cost-effective solution that can be designed to fit any room-specific needs for ACH, pressurization or other demands – where HEPA is not enough. The supply air flow in an operating theatre is commonly filtered by HEPA, which only collects particles of 0.3 μm and bigger in diameter.

Genano Technology® is based on electric filtering that removes the smallest nanosized particles down to 0,003 µm. The air circulates through Genano, where all microbes are eliminated in a powerful high voltage process.

At the end of the process, an effective active carbon collector removes dangerous gaseous compounds and smells. Our technology does not contain filters that can get clogged, therefore the purification efficiency stays high at all times and there is no pressure loss.

Air decontamination in NEST research laboratories - protecting operating personnel and preventing contamination of analyzed samples

Air decontamination in NEST research laboratories - protecting operating personnel and preventing contamination of analyzed samples

The high-intensity departments of the hospitals in Tuscany are equipped with Genano air decontamination devices

The high-intensity departments of the hospitals in Tuscany are equipped with Genano air decontamination devices

Corona Infection Centre that avoided staff related infections

Corona Infection Centre that avoided staff related infections

Wuhan Tongji Hospital

The First Affiliated Hospital of Guangdong Medical University

Yifu Hospital Affiliated to Nanjing Medical University

Al Ahsa Central Hospital

Dammam Central Hospital

Dhahran Eye Hospital

Dhahran General hospital

Mohamed Ben Naser Jazan

Omran hospital

Prince Sultan Cardiac Centre Madinah

Prince Sultan Military Hospital Madina

Qatif Central Hospital

Saad Hospital

We're proud to be transparent about the real efficacy of Genano Technology®. In this downloadable you will find the test reports with clear summary points about the most relevant findings.

Patented technology for collecting and eliminating viruses

Genano’s technology not only collects viruses and bacteria like typical air filters, it also eliminates particles down to a nano-scale, eliminating the risk of contagion from the device itself.

Genano Air Decontamination units are being used widely in COVID-19 testing centers, PCR testing laboratories for SARS-CoV-2, isolation wards and intensive care units.

Genano Air Decontamination Units equipped with a negative pressure kit are the fastest and most cost-effective way to rapidly set up isolation rooms – flexibly according to need. Genano has helped hospitals stop airborne infection routes already during SARS and MERS epidemics.

An independent research institute VTT (Technical Research Center of Finland) states that Genano Technology® eliminates 99,999% of viruses and bacteria from indoor air, including surrogate coronavirus.

High-end technology with service level to match.

Genano offers the cleanest air in the market, with ultimate safety of use. The patented technology makes sure that the electric air decontamination process occurs inside the unit, which means the air purifiers emit nothing else than ultra pure air.

Take a look at our introduction video to learn more about Genano Technology and why it is superior to other air decontamination technologies.

Genano solution is designed for medical facilities and laboratories where maximized hygiene is required. Our solutions are targeted for spaces where HEPA is not enough such as isolation wards, ICU/OT, clinics and laboratories.

• Removes Even Nano Sized Particles

• Eliminates Viruses And Bacteria 99.999%

• Adsorbs Gases And Odors

• Constant Clean Air Delivery Rate 24/7

Research test report of Genano - 99,999% elimination of indoor microbes

Download report

The risk of catching the coronavirus from surfaces is low

Read more

Lancet lists 10 scientific reasons why SARS-CoV-2 is airborne

Read moreContaminated air is led inside the unit.

Particles are charged negatively in a powerful corona discharge.

The negatively charged particles are attached to the positive collection chamber. Organic microbes are destroyed with electronical shocks.

Finally, the air is lead to active carbon collector which effectively removes VOC gases and odors.

Outcoming ultra pure air is completely free from particles of all sizes, microbes, and harmful gases and chemicals.

Many units have an automatic washing function which reduces the need for maintenance and keeps the cleaning efficiency high at all times.

Designed and made in Finland. Patented air decontamination solution for healthcare facilities. Easy plug and play installation, easy to move where needed, energy efficient in use.

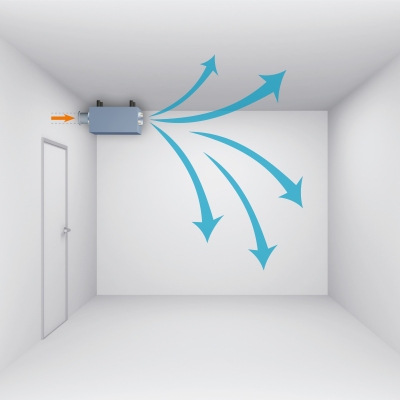

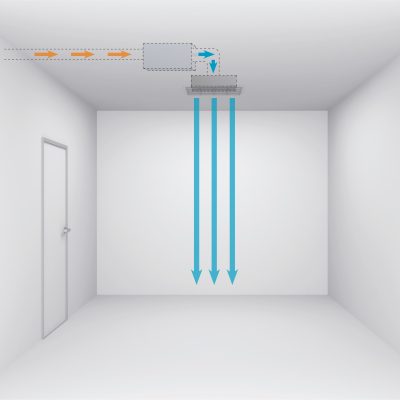

Duct Filter cleans impurities of all sizes from the incoming air.

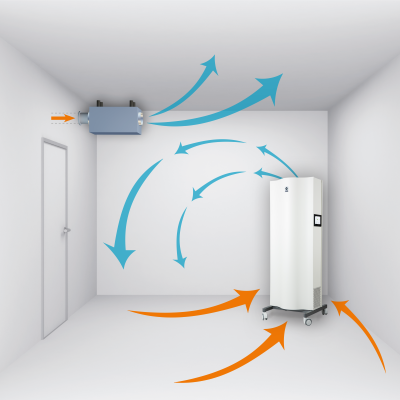

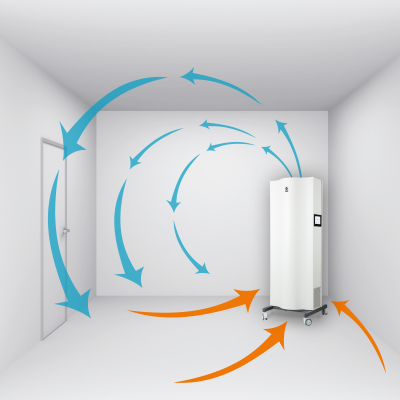

Genano stand-alone purifier ensures contaminants within the room will be eliminated by capturing particles from the room air.

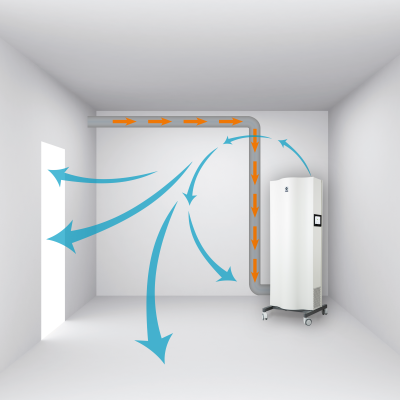

The supply air of the central ventilation is led into the room through the Genano air purifier

The device is capable of controlling the positive pressure difference, which should be 5–10 Pa relative to adjacent spaces. To obtain maximal results, the supply air should be at least 20 % more than the exhaust air and the air leakage should be under control.

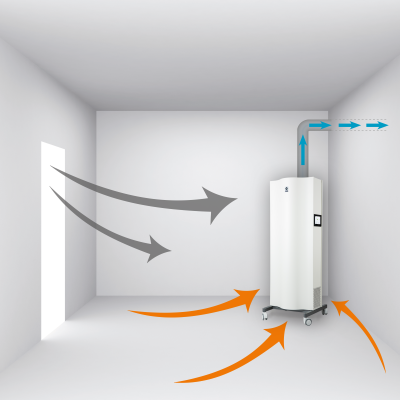

With a negative pressure kit, the stand-alone air contamination unit can be connected to the existing ventilation system

for creating a negative pressure into the room, while removing the airborne contaminants from the air.

Application areas for example: Microchips, Electronics, Optical, Bioindustry, Food industry, Pharma R&D rooms, Semiconductors, Silicon wafers, Nano technology, ALD, coatings, Food & Agricultural, Drug & Pharma, General industry labs i.e. petrochemical, etc.