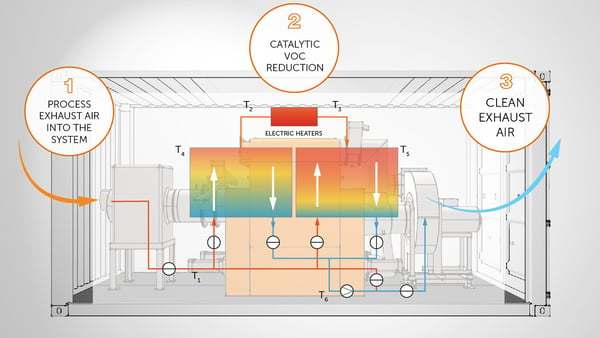

The Genano VOC system can be easily implemented into your production facility. Simply connect your process exhaust gas pipe and chimney to oxidizer along with electricity and pressured air. Instead of a traditional thermal oxidation, our system is based on ecological and efficient catalytic oxidation reaction. Outcoming air is free of VOCs and can be exhausted directly to outside air.

The oxidizer contains two or three chambers operating in a regenerative mode.

In the three bed technology, the contaminated air passes through the first chamber, heated up from previous operation. The air temperature is raised to minimum 300/350°C allowing the oxidation of the VOC within the catalyst.

In the three bed technology, the contaminated air passes through the first two chambers, heated up from previous operation. After the first oxidation process the hot air stream divides in two and passes through two different chambers with catalysts and heat exchangers, being cooled and heating the mass in the process.

If the VOC concentration of incoming air is not enough to keep the temperature above 300/350°C, then the heating system located inside the reactor will heat the air stream further for the needed time.

During the whole process the air stream is sucked by the main fan and goes through the chimney.

The outgoing air is completely treated and can be used for other heating purposes due to its temperature.

During the start-up of the VOC oxidizer and also in some situations where we don’t reach the ATP – Auto Thermal Point, additional heating energy is required.

The heating system is operated by electricity due to its ease of maintenance and required relatively small size but can be also optioned with gas heating. See All.1

The system includes a control unit by which all necessary and emergency functions of the catalytic VOC oxidizer can be controlled. The control unit is provided with all necessary inputs and outputs needed for remoting.

The system includes all instrumentation and electrical equipment needed in normal operations as well as in emergency situations.