Genano Healthcare Concept

– Modular solutions fit any hospital specific needs

1. Isolation Room Concept – Genano has a turnkey solution for hospitals

Biorisk reduction combines expertise and advice on high-consequence pathogens with guidance and training on safe handling and control of disease agents that pose significant health risks, with potential for adverse economic impact and public concern.

The goal of biorisk reduction is to ensure that current scientific knowledge regarding viral hemorrhagic fevers, epidemic-prone orthopoxviruses, and emerging severe zoonotic diseases affecting humans, is maintained in order to apply the most appropriate guidance for treatment, control, and safety to mitigate the risks regardless of the source of the disease event.

Experience is gained through outbreak response, managing clinical and laboratory environments, networking with subject matter experts and developing partnerships with stakeholders.

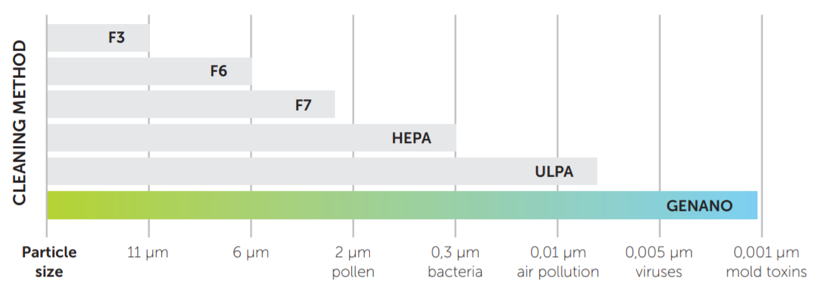

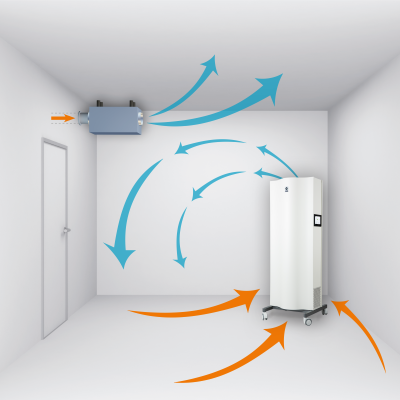

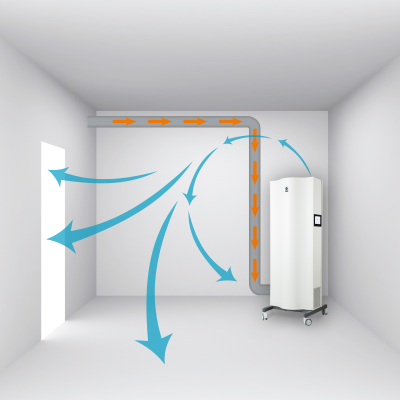

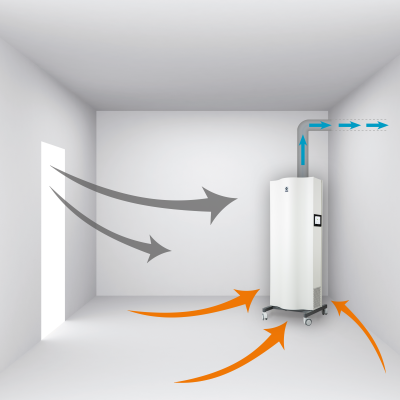

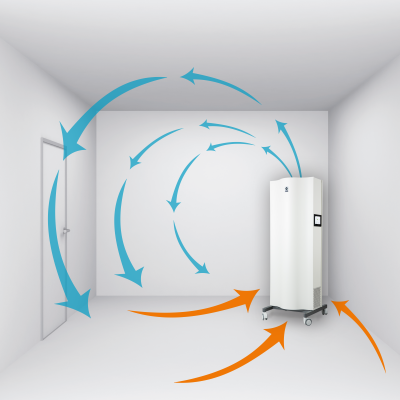

As part of biorisk prevention procedures, one of the main concerns is the ability to isolate the disease or the infected patients. This can be achieved by having Isolation Rooms, where the exhausted air is not recirculated but instead first filtered and then directed outside the premises.

.png)